JEOL is advancing the field of 3D printing with the JAM-5200EBM, an electron beam metal additive manufacturing (AM) system designed to meet the demands of modern production. Leveraging JEOL’s expertise in electron optics and precision engineering, this system is built for high-performance, high-reliability manufacturing.

The JAM-5200EBM enables efficient, clean production of lightweight parts - ideal for aerospace, energy, and other high-performance industries. It supports faster development cycles and higher output through precise, repeatable modeling, part integration, and significant weight reduction.

JEOL Additive Manufacturing Technology

Drawing on decades of experience in electron microscopy and electron beam lithography for semiconductor manufacturing, JEOL has developed an electron beam AM system that delivers greater power, beam density, and processing speed than typical laser-based systems. This leads to improved productivity, cost efficiency, and enhanced design flexibility.

Image Credit: JEOL USA, Inc.

JAM-5200EBM

Long Life Cathode over 1500 Hours and Helium-Free Electron Beam Metal AM Machine

Main Features

- Automatic Electron Beam Correction

- Helium-Free and powder dispersal prevention system "e-Shield"

- JEOL USA established, extensive service support organization

- Long Life Cathode

- Remote Monitoring System

- Realization of an eco-friendly and sustainable society

The JEOL Advantage for Additive Manufacturing

- Emphasis on maximizing system uptime with a long-life cathode rated for over 1500 hours. Cathode longevity and consistent manufacturing quality are supported by a clean production environment.

- The system operates in a helium-free setting with an “e-shield” that prevents smoke events during manufacturing. JEOL’s proprietary powder dispersal prevention system effectively eliminates scattering.

- Electron beam focus and spot shape are automatically corrected based on irradiation position - technology developed in-house, drawing on JEOL's leadership in electron beam lithography for semiconductor manufacturing.

- Includes remote monitoring for real-time visibility into system conditions and manufacturing status.

- Eco-conscious design supports building multiple parts in a single run.

- Manufacturing capacity: Up to 250 mm in diameter and 400 mm in height.

- Supported by JEOL USA’s established service network, with over 180 field service engineers nationwide.

A 3D Printer Built on JEOL Expertise and Support

What sets the JEOL JAM-5200EBM apart in the expanding metal additive manufacturing space is its foundation in JEOL’s decades of experience in advanced electron optics, developed for both research and industrial use.

As a market leader in electron microscopy, JEOL already plays a key role in the 3D printing value chain, from materials characterization and particle analysis to imaging and chemical analysis.

The JAM-5200EBM’s electron beam technology also builds on over 50 years of expertise in designing and producing mask writing and spot beam lithography systems, all supported by JEOL’s proprietary vacuum technologies.

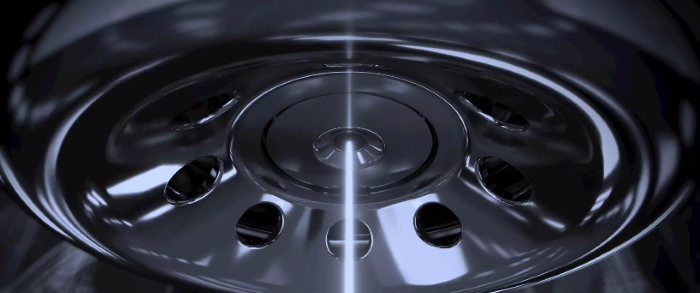

Long Life Cathode

The Long Life Cathode, with a lifespan of over 1500 hours, significantly reduces downtime associated with cathode replacement. Its durability is made possible by JEOL’s proprietary vacuum technology, which was developed through decades of experience in electron beam equipment manufacturing.

Image Credit: JEOL USA, Inc.

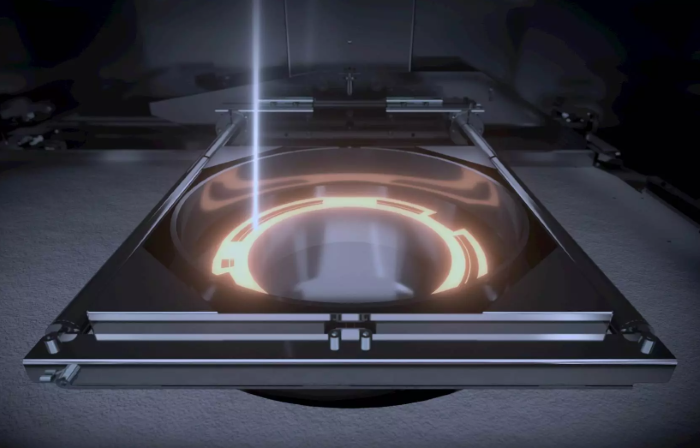

Helium-Free and Powder Dispersal Prevention System “e-Shield"

There’s no need for helium gas to prevent powder scattering. JEOL’s specialized powder dispersal avoidance mechanism effectively eliminates this issue. As a result, the cathode surface is less prone to damage, helping maintain a stable electron beam.

This helium-free environment also supports a cleaner manufacturing process, ensuring high production quality is maintained throughout the full lifespan of the cathode.

Image Credit: JEOL USA, Inc.

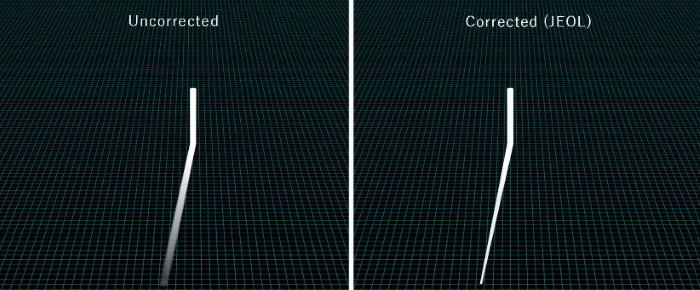

Automatic Electron Beam Correction

The focus and spot shape of the electron beam are automatically adjusted based on the irradiation position, using technology developed through JEOL's work in electron beam lithography systems for semiconductor manufacturing.

Image Credit: JEOL USA, Inc.

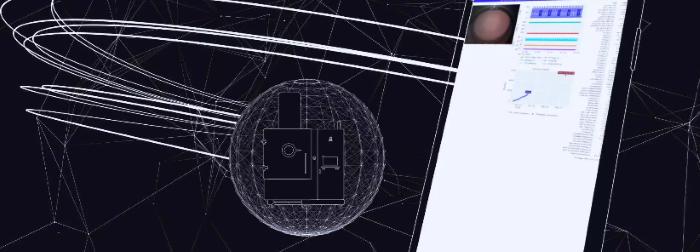

Remote Monitoring System

Manufacturing status and machine conditions can be monitored remotely at any time, with an alarm notification feature available for added oversight.

Image Credit: JEOL USA, Inc.

Realization of an Eco-Friendly and Sustainable Society

With JEOL’s Electron Beam Metal AM Machine, multiple parts can be produced in a single print run. Minimal cutting is required, which helps reduce material waste, and the ability to reuse metal powder adds to its efficiency.

Through these capabilities, JEOL supports the move toward a more eco-friendly and sustainable manufacturing approach.

Image Credit: JEOL USA, Inc.

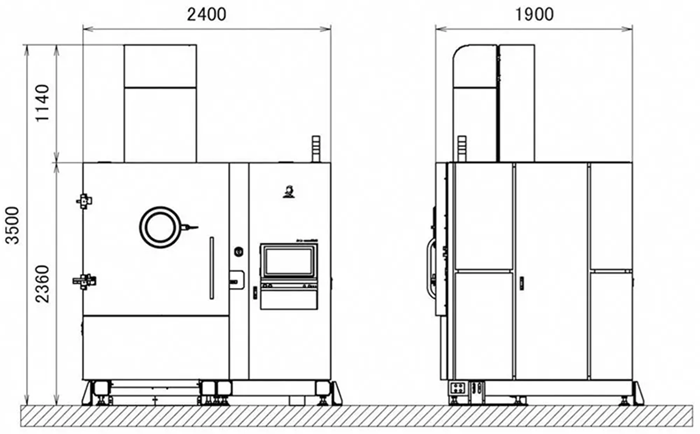

JAM-5200EBM Technical Data

Dimensions. Image Credit: JEOL USA, Inc.

Main Specifications. Source: JEOL USA, Inc.

| |

|

| Manufacturing method |

Powder bed fusion |

| Manufacturing dimensions |

Maximum 250 mm (Dia.) × 400 mm (H) |

| Electron beam output |

Maximum 6 kW |

| Lifetime of cathode |

1500 hours or longer |

| Chamber pressure (during melting) |

0.01 Pa or lower |

| Inert gas (for charging prevention) |

Not required |

| Manufactured product cooling system |

Equipped |

| Powder dispersal prevention system |

e-Shield |

| Beam correction |

Automatic (Focus, Astigmatism, Distortion) |

| Power supply |

3-phase, 200 V (±10%), 35 kVA |

| Weight |

4900 kg |

| Data format |

STL |