The Cross Section Polishers™ (CPs) are a popular broad ion beam milling equipment for preparing specimens for electron microscopy. The CP eliminates artifacts associated with typical mechanical preparation methods, resulting in pristine cross sections of challenging specimens such as brittle materials, multilayer coatings with different hardness or thermal expansion, fragile porous materials, polymers, and composites, and so on.

The result is a high-quality cross-section with an artifact-free surface, perfect for imaging and microanalysis (EDS, WDS, EBSD) using SEM, EPMA, or Auger.

Choose between the Cross Section Polisher™ (IB-19540CP) and the Cooling Cross Section Polisher™ (IB-19550CCP) for thermally sensitive materials. These new setups include a High-Speed Milling Source for extremely quick preparation (up to 1.2 mm/hour on Si).

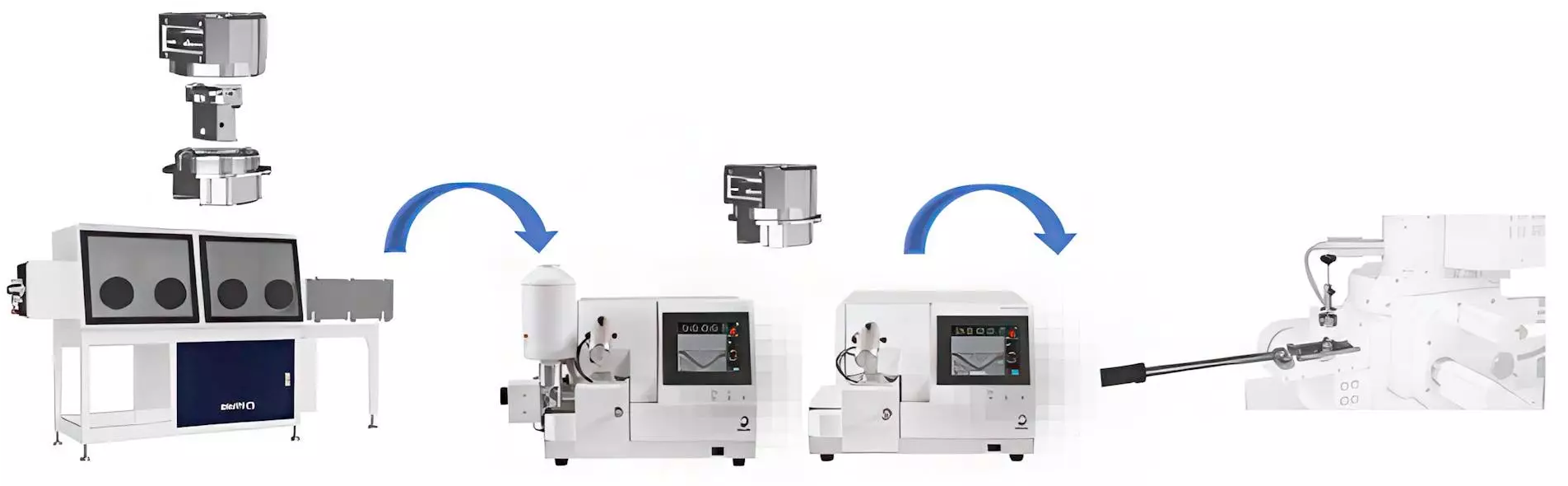

Air Isolation Workflow options are available for rapidly preparing and transferring air-sensitive specimens.

Cross Section Polisher™ (shown left), Cooling Cross Section Polisher™ (shown right). Image Credit: JEOL USA, Inc.

Key Features

High-Speed Milling Source

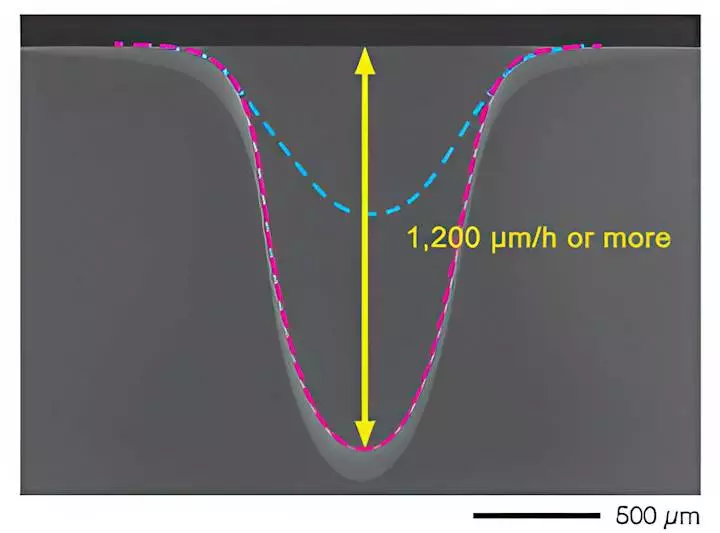

Specimen: Si; Ion Energy: 10 keV, Milling Time: 1 hour. Image Credit: JEOL USA, Inc.

All CP configurations have an enhanced high current density ion source, which allows for an ion beam accelerating voltage of up to 10 keV and ultra-fast milling rates of up to 1.2 mm/h.

Modes for intermittent milling (automated duty cycle for beam-sensitive specimens) and fine milling (low-voltage fine finish of specimen surfaces, excellent for procedures like EBSD) are included.

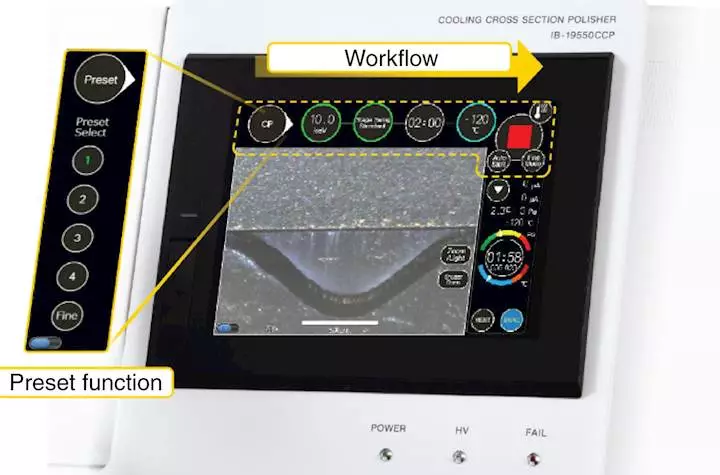

User-Friendly Software Interface – Guided Workflow - Remote Control Enabled

The new remote-enabled flow chart-style control panel takes users through the setup process. Preset capabilities enable users to save and remember process conditions for quick and optimal setup of various specimen types. There is an autostart function built in.

Milling Monitoring Camera – Option

Image Credit: JEOL USA, Inc.

Set up the Milling Monitoring Camera to watch and control the milling process. Connect to your LAN for remote access and management. The milling process can be followed, monitored, and adjusted using a web browser.

Image Credit: JEOL USA, Inc.

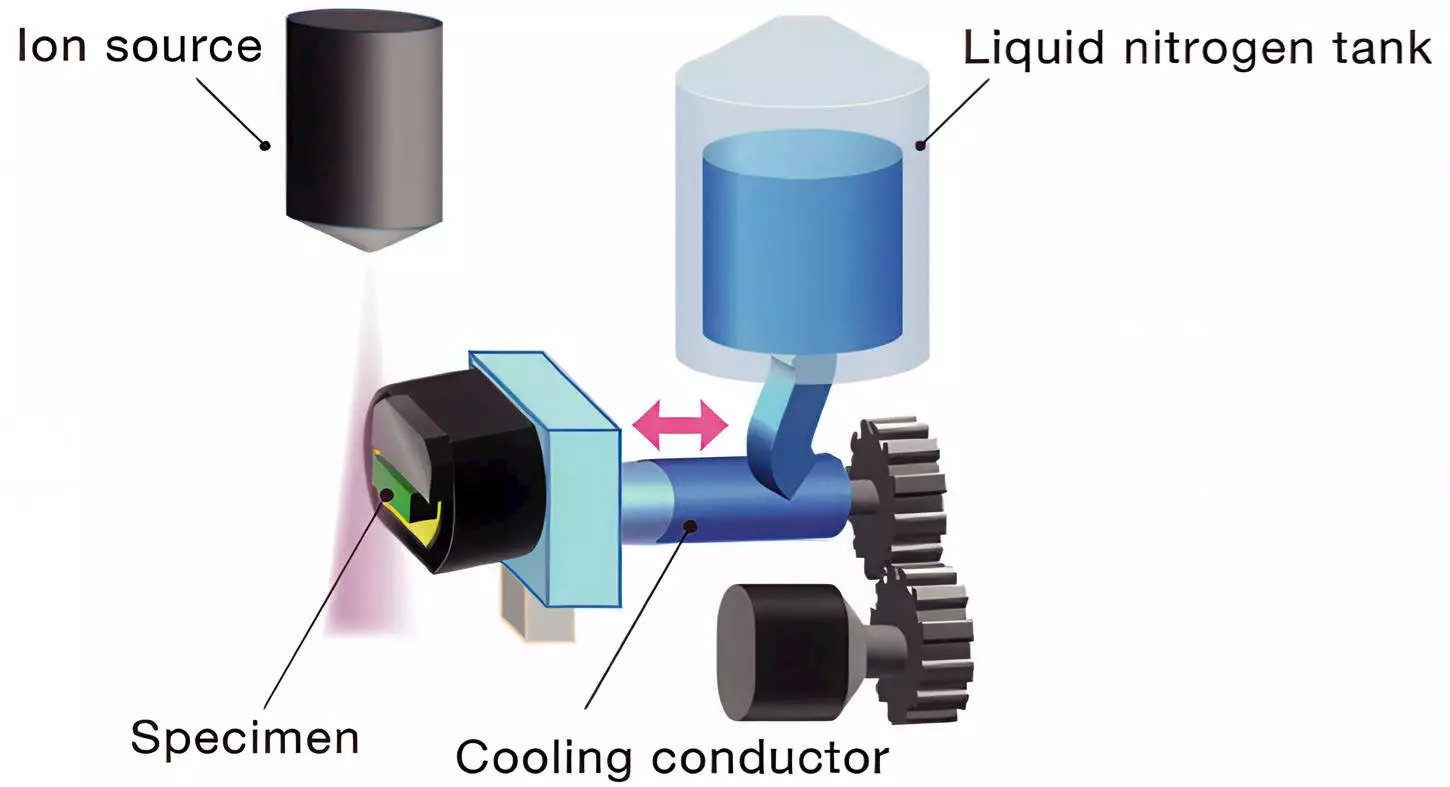

Cooling Cross Section Polisher™ - Auto Cooling and Auto Return to Room Temperature

It is ideal for preparing thermally sensitive materials such as polymers, solder, metallic lithium, and galvanized steel. The novel design enables extended cooling retention time while conserving liquid nitrogen.

Image Credit: JEOL USA, Inc.

- Mill continuously at –120 °C for at least 8 hours

- After the milling operation, the system can be configured to automatically cool down to room temperature

- Even in the presence of liquid nitrogen, specimen exchange is possible

Multi-Purpose Stage

It fits a wide range of sample holder choices, including large-area milling, planar milling, carbon sputter coating, and air isolation transfer. Standard holders are fully compatible with JEOL SEM stages and allow direct transfer. The Specimen stage swing feature guarantees artifact-free surfaces.

Air Isolation Workflow – Option

A transfer vessel system is available for samples that are reactive with air. After mounting the sample in a glovebox, it is sent straight to the JEOL SEM and subsequently to the Cross Section Polisher for milling.

Image Credit: JEOL USA, Inc.